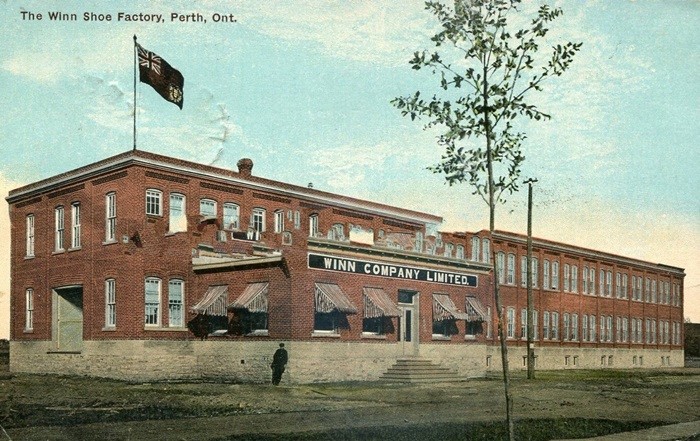

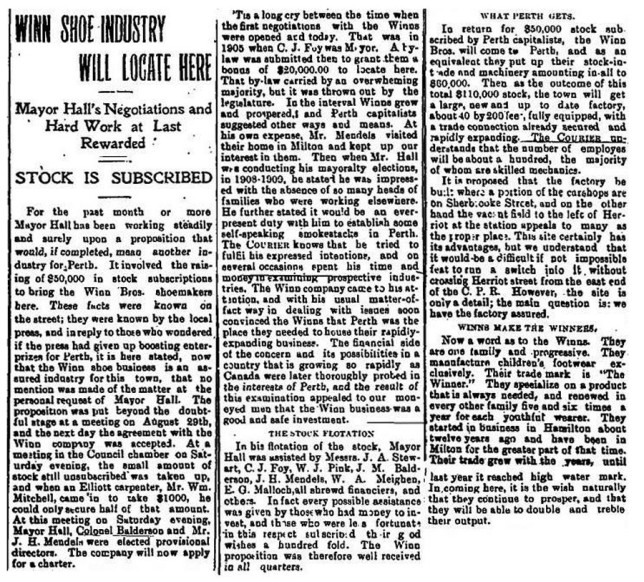

THE PERTH SHOE FACTORY 1905

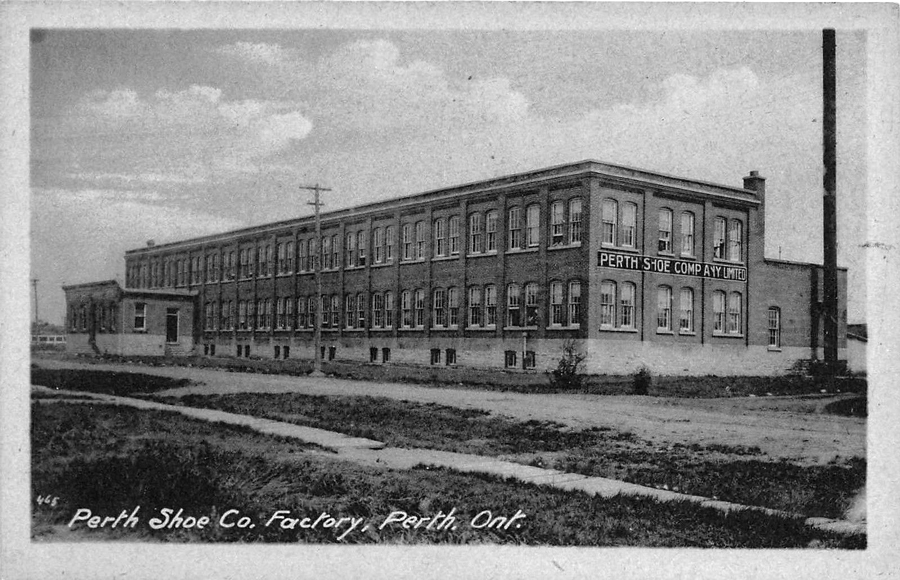

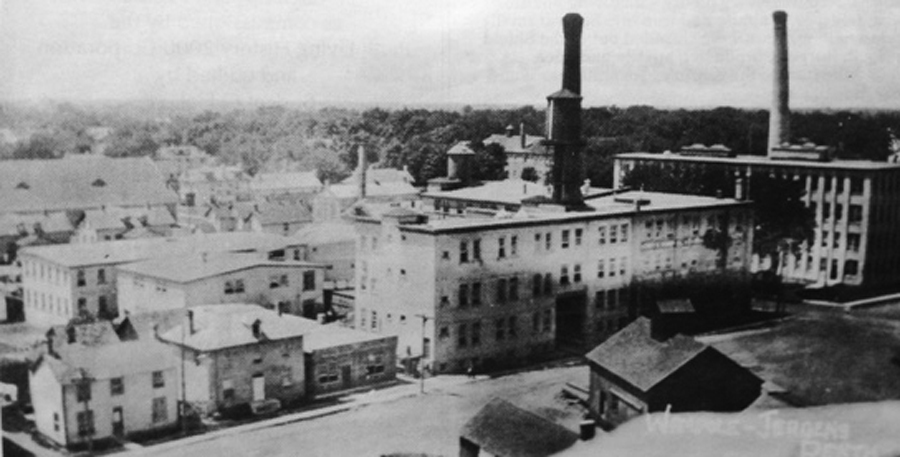

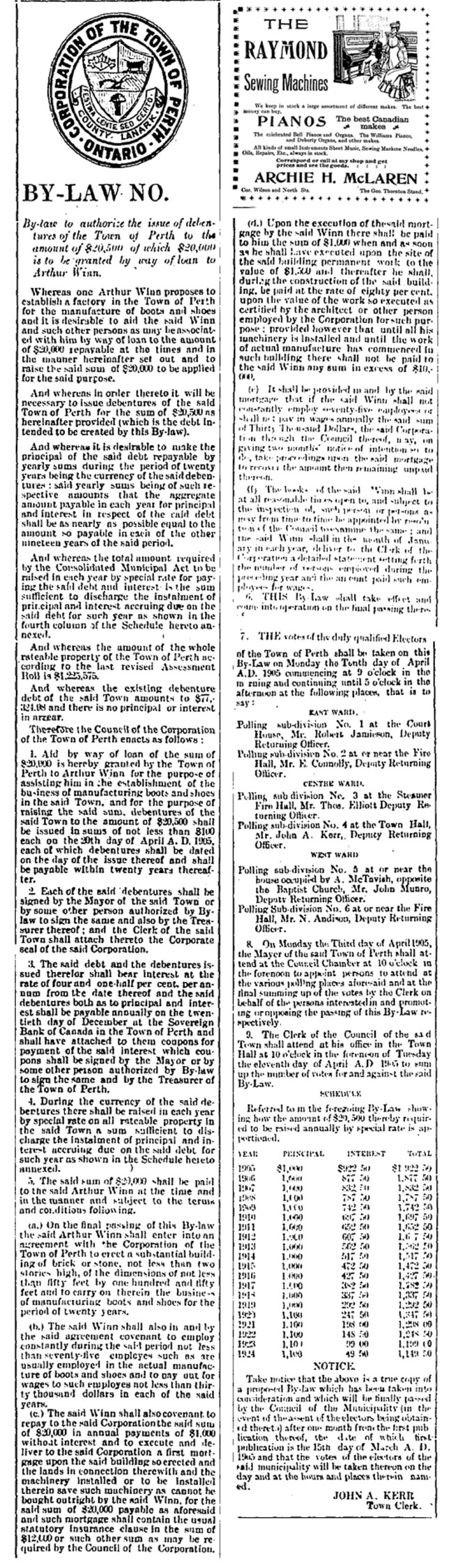

The Winn Shoe Company, U.S.A. established a new shoe factory at One Sherbrooke Street, Perth. A beautiful two story brick building of 17,000 square feet was erected between 1905 and 1910 where 500 pairs of shoes were produced each day and the total weekly payroll for all employees was over $500.00 per week. In 1912 the company was reorganized by F.W. Hall and C.J. Sewell and transformed into the Perth Shoe Company. Employment grew to 200 operators and 700 shoes per day were shipped from the factory.

The First World War (1914-1918) resulted in a dramatic increase in activity and production. Records indicate that 10,000 pairs of army boots were sold to the Canadian military in 1915 at a cost of $4.10 per pair. In October 1919 a complete third storey and forty foot eastend extension were added to the building bringing the entire production space to 30,000 square feet. An additional two storey 9000 square foot warehouse was added at the rear of the factory in August 1933 which was subsequently increased by another 4000 square feet in 1959 making the entire building approximately 45,000 square feet. It was the only factory in Canada devoted exclusively to Goodyear welted shoes for ladies, the famous Naturalizers. It was sold to Brown Shoe Company in 1954 who later moved to new locations at Sunset Boulevard and Rogers Road.

The Perth Shoe Company was acquired by the Brown Shoe Company in 1960 and after building a new manufacturing facility at another location at Sunset Boulevard and Rogers Road.The Brown Shoe Company continued to utilized the old building until 1982 as a storage centre to accommodate the growing demands of the company. The building has since been renovated to accommodate various businesses.

The Perth Courier 1905. By-Law to authorize the issue of debentures of the Town of Perth to the amount of $20,500 of which $20,000 is to be granted by way of loan to Arthur Win to establish a factory in the Town of Perth for the manufacture of boots and shoes.

THE BROWN SHOE COMPANY 1960

Left to right; Mr. J. Baugher, Director Manufacturing, Howard Scott, General Superintendent, Orval James, Plant Superintendent and the completed plant November 1st 1960.

The Brown Shoe Company Plant situated on Sunset Boulevard, manufacturing Naturalizer, Air Step, Dr. Locke, Scholls and Perth Welts was competed on November 1st 1960. The Company employed 360 people in the Town of Perth, with a payroll of over a million dollars per year. The Plant, one of the most modern in North America, is of similar design to other factories in the Brown Shoe family. A second plant was opened in Alexandria in 1959, where the Buster Brown, Miss America and Pedwin shoes are manufactured. In the Perth plant, 19,200 shoes were in process each day of the week. In the U.S. at the time there were fifty planes, including tanneries and other factories manufacturing the various component parts.

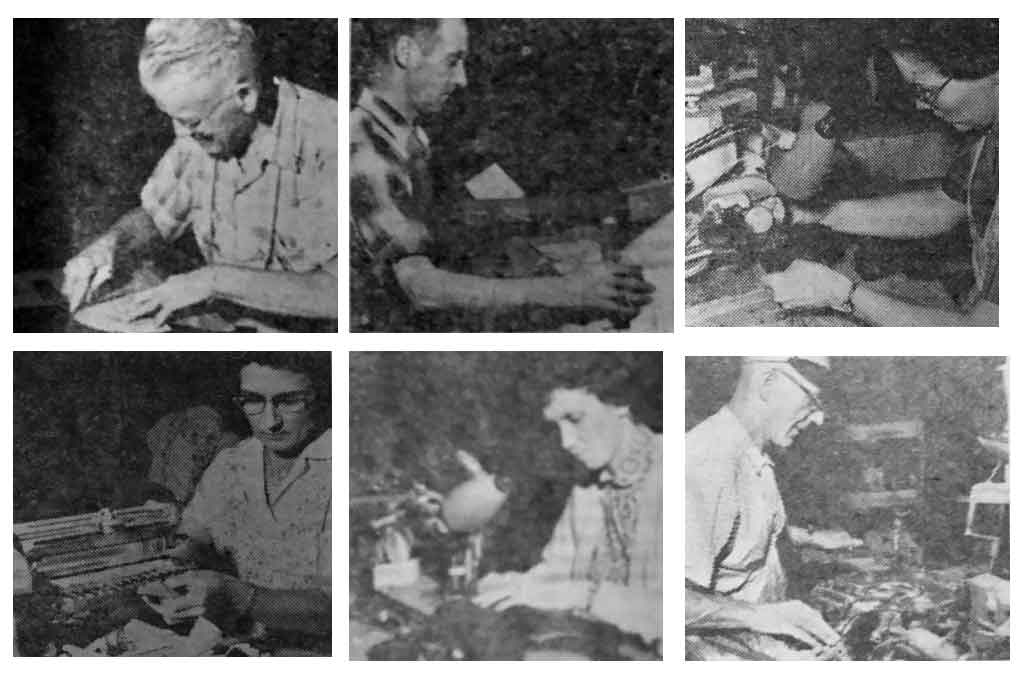

BROWN SHOE COMPANY 1961 Top left to right; George Thompson cutting the vamps by hand from calf skin, Jack Buchanan, cutting vamps by machine, Pat Stafford, stamping various parts of the shoe for assembly. Bottom left to right; Cementing cloth for shoe lining by Agnes Love. Shirley Jackson closing the back seam of the shoe, Everett Cain, toe lasting (old style).

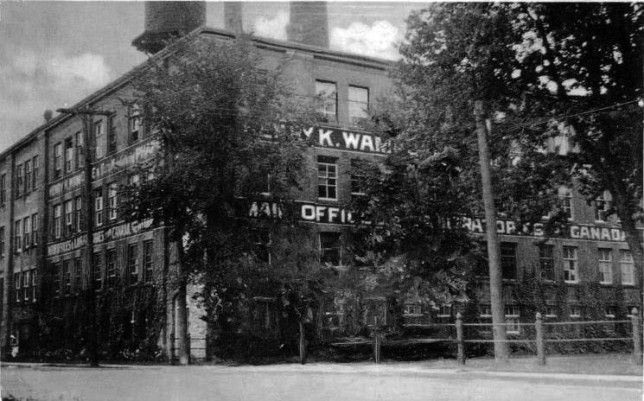

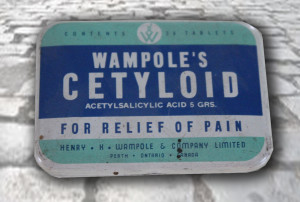

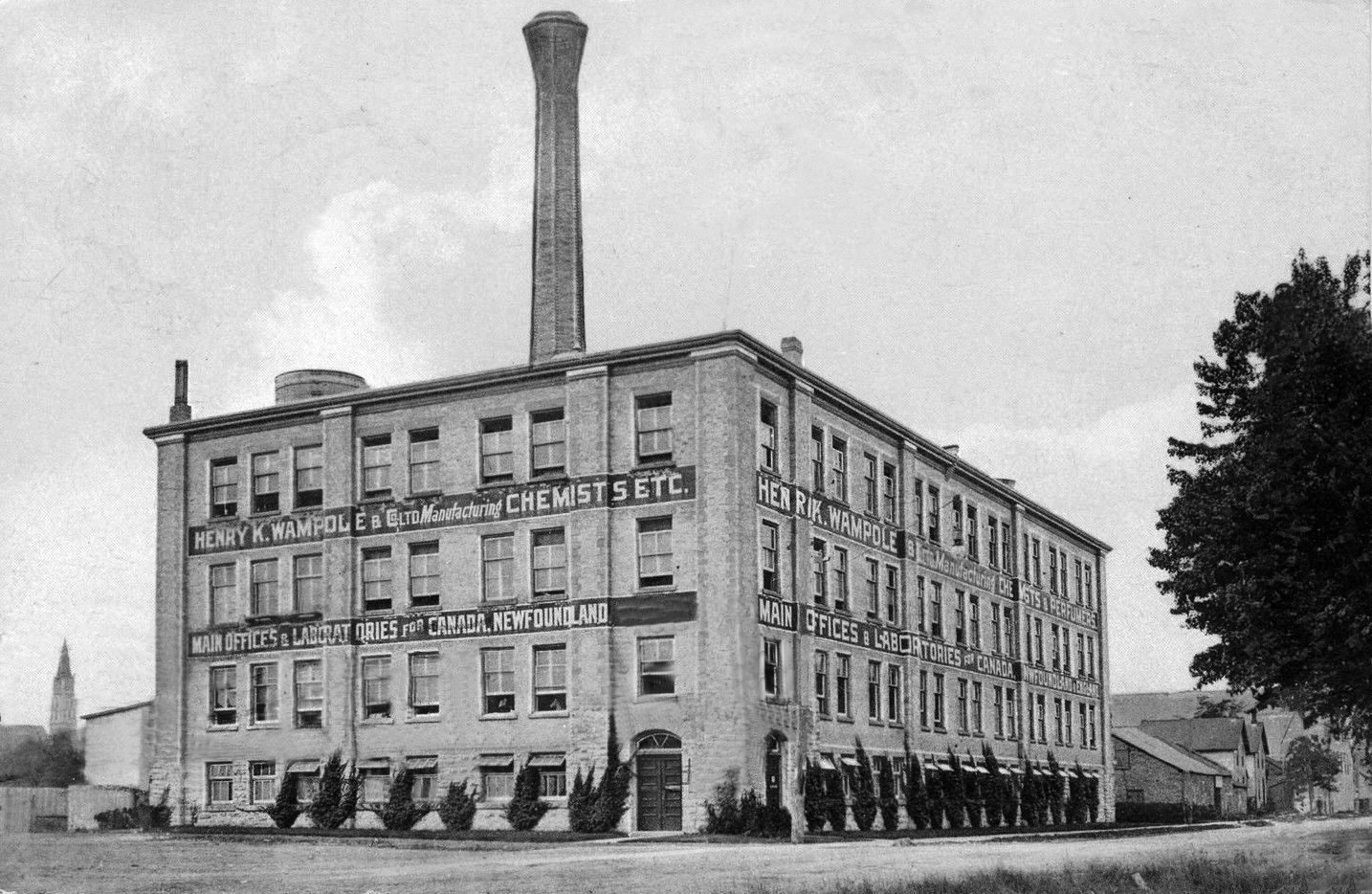

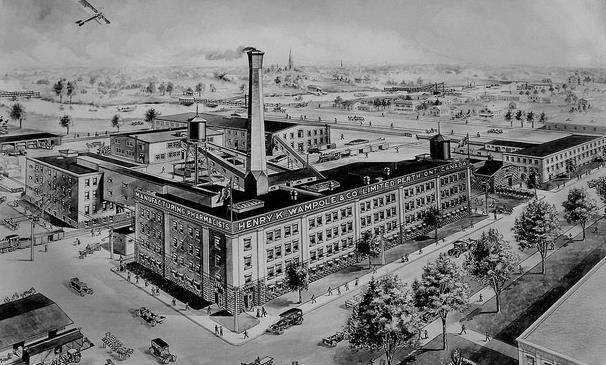

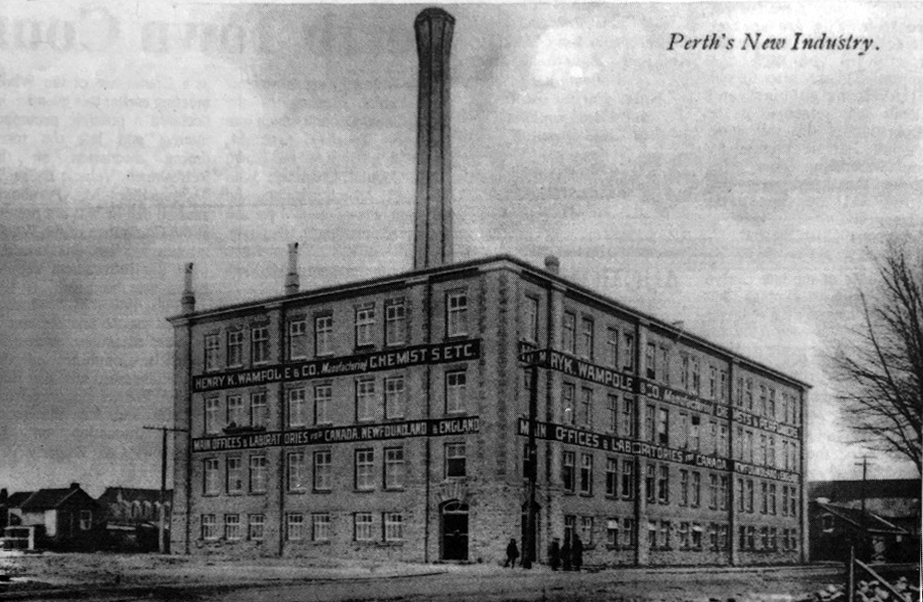

HENRY K. WAMPOLE LABORATORIES – 1905

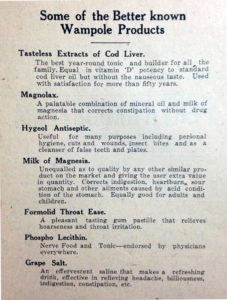

Wampole’s manufactured many pharmaceuticals in Perth. WAMPOLES GRAPE SALTS SAMPLE TIN FROM HENRY K. WAMPOLE & CO. LIMITED PERTH ONTARIO. “Cleanses the system..cools the blood” slogan. Tin is circa 1910.

Henry K Wampole Company established in Perth in 1905. The original building situated near the Jergen’s Factory and the Perth Shoe Factory, later the Brown Shoe Factory, close to the Perth Railway Station. Wampole’s later moved to a modern building in the late 1960’s situated on HWY 7 and that building has since been torn down as well.

Another shipment of pharmaceutical products is trand=fered to a CPR freight car at the rear of the Henry K. Wampole Company, Perth. This and similar supplies are shipped regularly to the British Isles, Asia, Australia nad other distant point around the world.

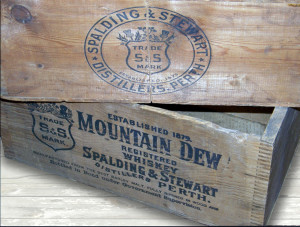

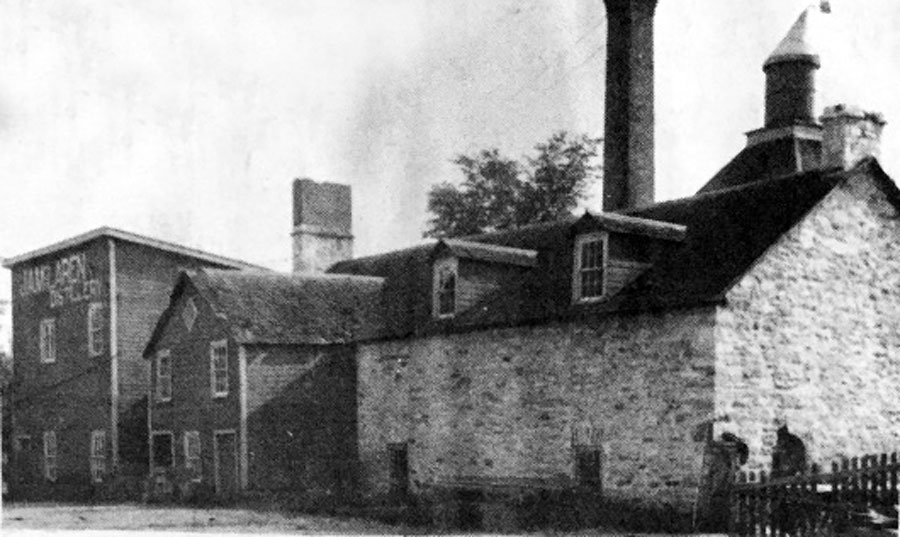

SPALDING & STEWART DISTILLERY

A stone building was erected around 1830 at 106 Gore St for use as a brewery by William Lock. This was built on the site of the Kings Store, a log building previously owned by William Morris. The first still licence found was issued in 1838, for a coper still (Larry Cotton in Whiskey and Wickedness – Upper Rideau River Valley, indicates that Lock had two copper 44 gallon vats). Sometime before 1837, Lock purchased the Summit house on Drummond St. and built a stone building (for use as an Inn) between it and the river. A dock facility was added, where the boat the Jolly Brewer was berthed. It was from this stone building to the Lock distillery on Gore St. that the famous tunnels ran. The purpose of these tunnels has long been debated, however I believe that they were used to transfer alcohol (mostly beer) from the brewery/distillery to the inn and hence the Jolly Brewer, which made numerous trips to Kingston carrying beer. In the winter the beer was transported on sleighs. By 1844, William had an inn licence, but no still licence. The brewery continued under Lock until about 1849, when it was sold to McEwen & Morris as a brewery, and continues as such under numerous owners until Spaulding and Stewart reopened the distillery in 1879.

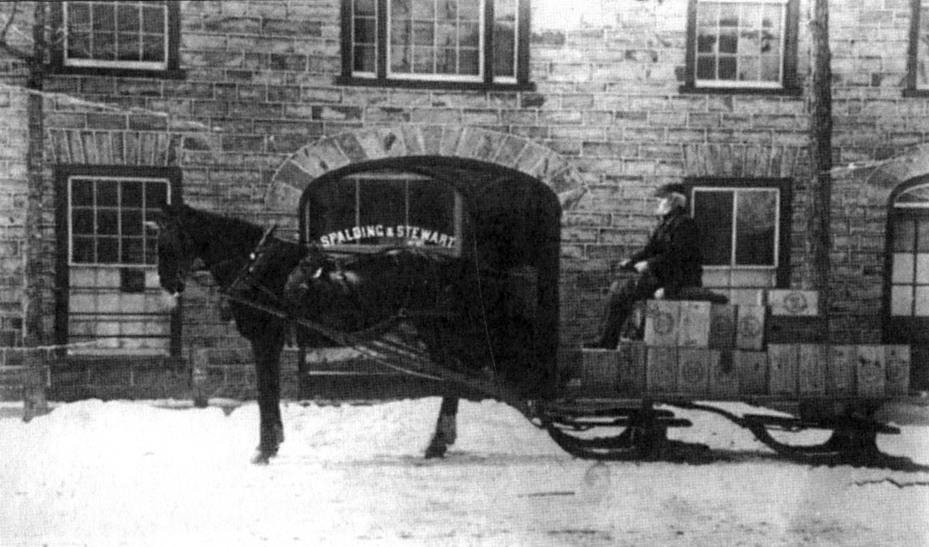

James Spalding, and Robert Stewart started a partnership about 1875, as brewers. By 1879, they had added the distinction of Distillers & Brewers, and in were also in possession of a Shop Licence. They were located on the property originally owned by William Lock, and it is believed that they used the tunnels built by William Lock as aging rooms for their whiskey. Their most famous brand was Mountain Dew. In 1910 Stewart left the partnership and Spaulding continued on his own. Although their whiskey in no way inferior to McLarens, they never gained the popularity that McLarens did, perhaps because they did not advertise with the over the top approach that J.A. did. This distillery also came to an end due to the 1916 legislation. The still was purchased by Wampole’s, for use in making the main ingredient in many of their medicines – alcohol.

Henry Kehoe sits on crates of whiskey ready for delivery from Spalding & Stewart Distillery. Photo: The Perth Courier

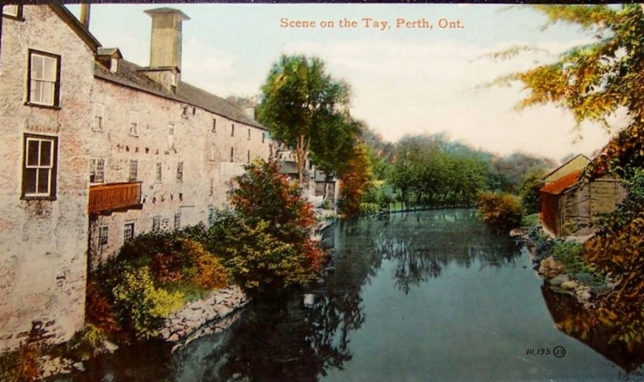

Original Gore Street Bridge over the Tay RIver with Spalding and Stewart Distillery original building in background.

History of the Gore Street Bridge. The Perth Courier, June 13 1957.

In the fall of 1815 a small group of men worked their way overland from Brockville. These men came ahead of the main group of settlers in order to discover the nature of this land that the Colonial Office in Britain had allotted them sight unseen. They made camp on the south shore of the Tay River for the night. In the morning they decided to explore the north shore but the river was too deep and cold at that time of year to make it comfortable to walk across. They set to work to cut down a huge elm tree on the river’s bank. This tree was the first bridge and it is believed that the first man to set foot in what is now Perth’s business section was Magnus Flett, The stump of that tree was preserved in the basement of what used to be Spalding’s Brewery.

The second bridge was built shortly after. The main body of pioneers came up from Brockville in the spring of 1816 and “The Military Colony of Perth” was established. One of the first undertakings of the settlers was to build a log bridge over the Tay. This project was not without incident. One of the workmen, William Holderess “took a violent fit of sickness” from working in the cold water of the Tay. He died as a result and earned the distinction of being the first victim of industrial fatality in Perth. Three months later, in July, 1816, his widow further distinguished the family name by presenting the settlement with its first new born child.

This log bridge served the community until 1832 when work was begun on a stone bridge. The “Old Stone Bridge”, as it was known, was a thing of beauty. It was a perfect Roman Arch, not too common even in those days. Most stone bridges rise five or six feet from the river’s edge before the arch begins but this bridge was a perfect arch from shore to shore.

Because of its beauty and singularity, the bridge brought the town a lot of publicity. Artists came to sketch it, and it was reproduced on tea cups and paper weights. There is an oil painting of the bridge hanging in the Perth Museum. By the 1890’s., the Rideau Canal had long been completed. The Tay Canal was in operation and the present Tay Turning Basin had recently been dredged.

Then, as now, politics took an active part in the lives of the town’s people. They were proudly represented in the federal cabinet by The Hon. John G. Haggart, who was Minister of Railways and Canals. It was under his supervision that the Sault St. Marie Canal was built an undertaking that was to bring Canada millions of dollars.

Unfortunately, the beautiful old stone bridge stood in the way of progress. It had to come down to make way tor the dredge and for the supply barges that would follow later. A legend has grown up that the old stone bridge fell down quite suddenly and unexpectedly on sunny summer’s afternoon. A great portion of it did fall suddenly, and although some of the workmen had a narrow escape its collapse was not unexpected.

The men had been working on the stonework under the bridge. This undermining and the blasting going on about it weakened the structure. The bridge came down on a July afternoon in 1891 at about two o’clock. Shortly afterwards, the river was deepened up to the mill and the new swinging bridge went up. Ironically, this new bridge that had taken so much effort to build, was swung only four or five times. Only a motor launch and occasional barges went up to the mill for supplies.

The old mill was finally destroyed in 1948 by a bad fire. Up until that time it had been in almost constant use. The bridge swung for the last time about 1905. It took eight men to operate it as the weights in the swinging mechanism had fallen off. Now we are to have a new bridge. The last remnants of the stone bridge are bing torn out and as on so many other occasions in Perth, history is making way for progress. In 1957 the fifth bridge over the Tay River at Gore Street near Harvey Street was built.

McLAREN’S DISTILLERY 1831

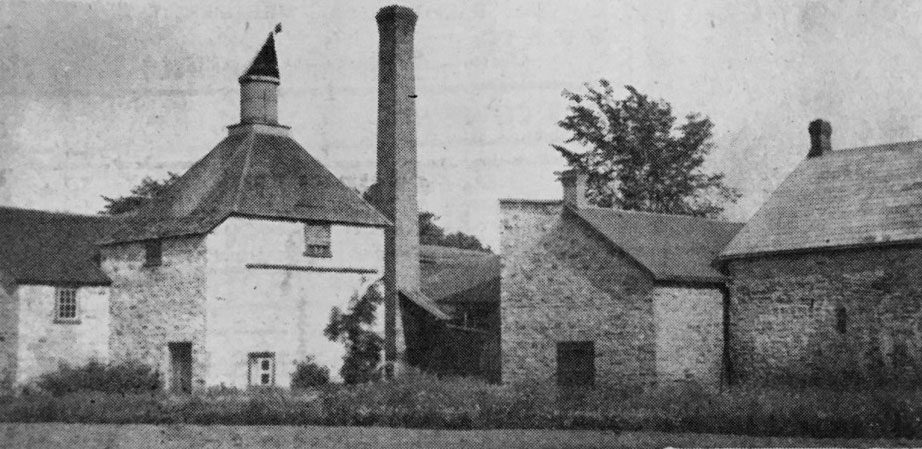

J.A. McLaren Distillery, Perth. Located back of the Town Hall in what is now Stewart Park. Part of the buildings spanned the Little River. Buildings demolished in 1916.

In 1900 a bottle of McLaren’s “old Perth malt whiskey” sold for 90 cents; 80 cents if you brought your own bottle. Today, an empty McLaren bottle with label intact sells for as high as $5 in antique shops across Ontario. One collector of old bottles predicted in twenty years the price for these fast disappearing artifacts of old Perth would go as high as $15 each. Full bottles of which there are still a few left just are not for sale at any price.

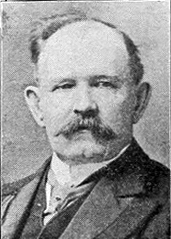

Despite the disparagement in prices now and in the old days, John A. McLaren, Perth’s whiskey king, managed to eke out a fairly comfortable living. In fact, he became one of the town’s wealthiest businessmen and his product was known to hundreds or thousands of Canadians from the Pacific to the Atlantic.

John A. was one of the first liquor manufacturers to put out what is known as “mickies” (12 oz bottles) on the Canadian market. The product came in amber with clear bottles the latter having a bluish tinge.

The McLaren distillery was founded in 1831 by Robert McLaren, father of John A. , who followed the traditions of the great Scotch whiskey manufacturers of his day, many of which are still going strong. “Old Perth Malt” had a unique flavor due to wood being used in the malt making, rather than peat as used in Scotland and Ireland. Its Canadian contemporaries were made in four days while McLaren was processed a full 30 days.

One of the wealthiest if not the wealthiest manufacturing establishments in Perth was the McLaren Distillery, located on what is now Stewart Park directly behind the home of Mayor E.S. Burchell on Market Square. Opposite the mayor’s house stood the McLaren stables, which boasted more than 100 bulls happily thriving on the mash left over from malt making.

Stewart Park might well stand today as a monument to John A. McLaren as well as to John A. Stewart for it was from the enterprising “booze king” that the Stewart fortune and holdings were acquired. Stewart, a relative of McLaren’s, was the principal heir in the malt maker’s will and himself became a national figure in business and politics. He served as M.P. for Lanark and entered the Bennett cabinet as Minister of Railways and Canals.

When John A. McLaren died at the turn of the century, Stewart continued the operation of the distillery along with other enterprises including the Henry K. Wampole Company and later the Perth Expositor. He was described as a shrewd businessman and opportunist as well as a master of litigation.

Perhaps Stewart’s finest display of legal finesse came with the handling of the McLaren will. Although he proved to be the legal heir, it took a bit of explaining to the powers that be before the fortunes of his kinsman could be added to Stewart’s coffers.

“Old Perth Malt Whiskey has gained such a high reputation among the judges of fine liquor it is regarded as non-injurious and has become a household staple where other whiskies would not be tolerated” said the proponents of the day.

Unfortunately, despite the eloquent pleas put forth by the hidden persuaders of yesteryear, the Ontario Temperance Act disagreed and in 1917 “Perth Old Malt Whiskey” along with its imitators was banished from the Ontario market. Prohibition had descended on the land and the whiskey sellers, the licensed ones at least, were left with empty shelves. Article from The Perth Courier

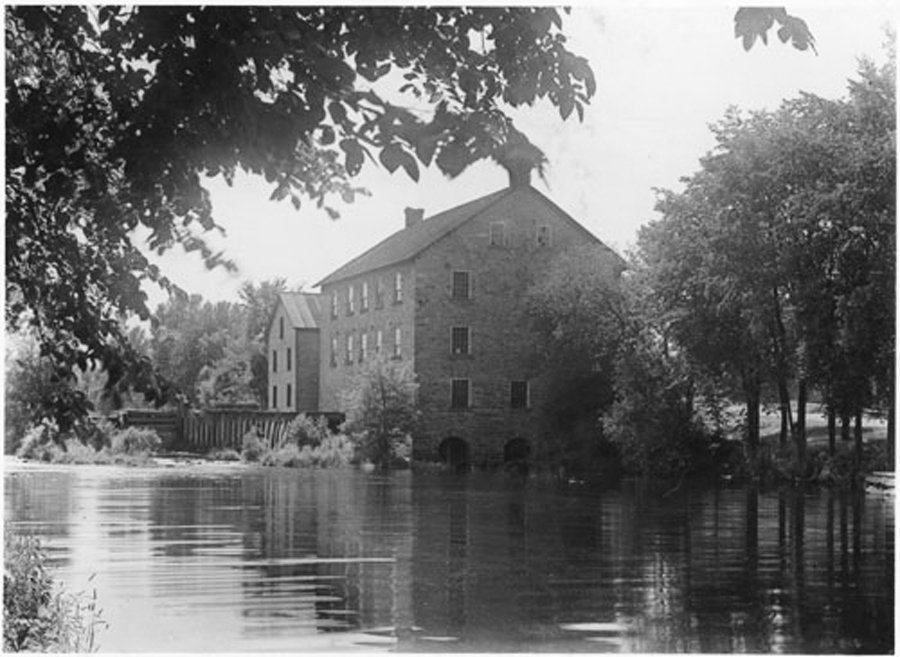

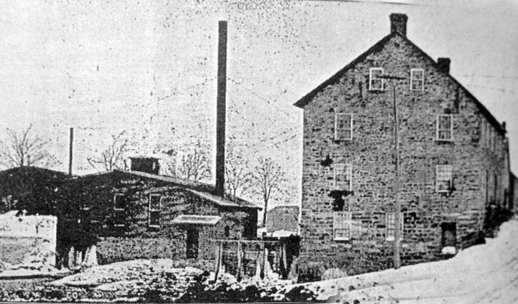

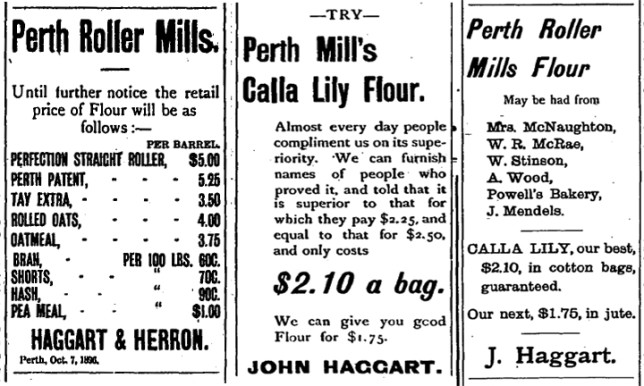

HAGGART and HERRON FLOUR MILL

This photo of Haggart’s Mill and Power Station was located on the Tay River near Mill Street and was a major business venture in its day

The original frame structure in which to grind flour was erected by Dr. Alexander Thom in 1817, and acquired by John Haggard in 1834, He was a native of Breadalbane Scotland, trained as a stone mason and engaged as a contractor on the building of the Welland Canal and then the Rideau Canal. The mill produced flour, behind it an oat mill producing oatmeal, beyond that a saw mill and at the Little River dam a carding mill. About 1837 he erected a stone residence on the highest part of Haggart’s Island described in the Canadian Geographical Journal in 1949 as “an outstanding example of Regency building in severe Scottish mould”. In 1896 Mr. Haggart joined with James Herron and produced daily 75 barrels of flour. The picture to the right shows, The Haggart Mill, destroyed by fire in 1948, and was the last surviving building of Perth’s first industrial complex.

The original frame structure in which to grind flour was erected by Dr. Alexander Thom in 1817, and acquired by John Haggard in 1834, He was a native of Breadalbane Scotland, trained as a stone mason and engaged as a contractor on the building of the Welland Canal and then the Rideau Canal. The mill produced flour, behind it an oat mill producing oatmeal, beyond that a saw mill and at the Little River dam a carding mill. About 1837 he erected a stone residence on the highest part of Haggart’s Island described in the Canadian Geographical Journal in 1949 as “an outstanding example of Regency building in severe Scottish mould”. In 1896 Mr. Haggart joined with James Herron and produced daily 75 barrels of flour. The picture to the right shows, The Haggart Mill, destroyed by fire in 1948, and was the last surviving building of Perth’s first industrial complex.

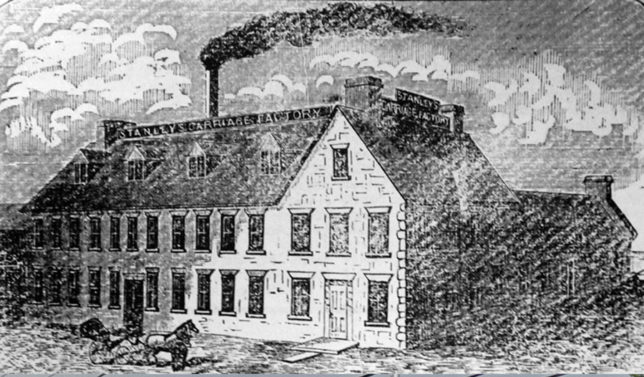

STANLEY CARRIAGE WORKS 1886

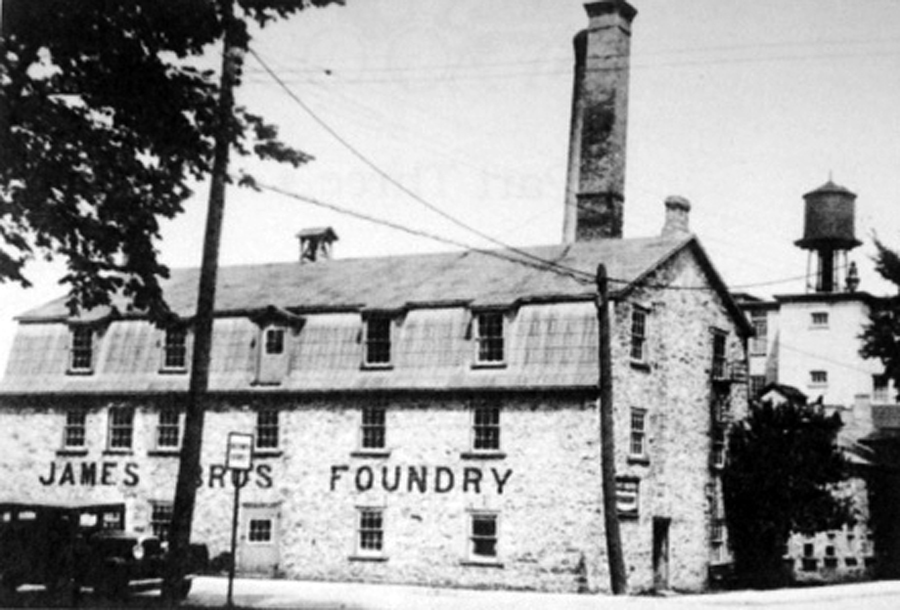

JAMES BROTHERS FOUNDRY

Photo taken outside James Brother’s Foundry 1910. Shown here are W. Bates and D. Mayall on a cart with a shipment of sleighs from James Brothers bound for Montreal. This photo can be seen at the Perth Museum on Gore Street along with other items from the foundry.

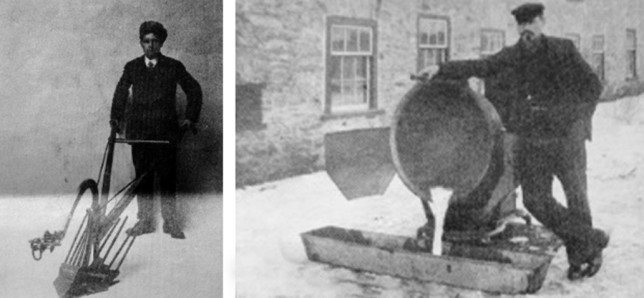

Jim Montgomery with latest plow and to the right, where it all begins. Photo: Perth Courier (courtesy Alan James).

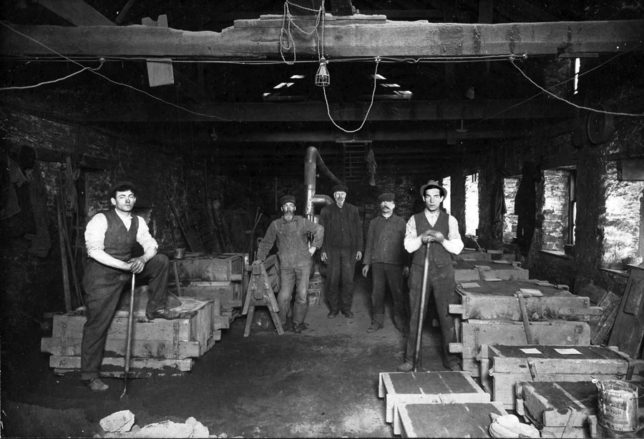

Photo was taken at the James Brothers Foundry on Herriott Street circa 1930. The gentleman on the left of the picture with his leg up is John W. Harper. Photo courtesy; John T. Harper.

TAY KNITTING MILL 1882 • CODE FELT MILL

The first industrial process on the site was operated by the Kilpatrick family beginning in 1842 and established as a tannery shortly thereafter. In 1882 a new owner, Thomas Alfred Code, established Codes Custom Wool Mill with a range of processes, including: carding, spinning, fulling, shearing, pressing, and coloring of yarns. In 1896, its name was changed to the Tay Knitting Mill, and it produced yarn, hosiery, socks, gloves, sporting-goods, sweaters, and mitts. Another change came in 1899, when a felt-making process was introduced and the mill was renamed Code Felt. The company continued to operate until the closing of the factory in 1998.

Aerial View of the Code Factory on Rogers Road at Harvey Street. Perth Creamery is seen across the street.

PERTH TEXTILES

Perth Textile Plant, also known as Tayside Textiles. Originally known as Perth Carpet Factory established in 1911. The buildings were situated along the old Perth Tay Tow Path.

STAFF PHOTOGRAPH TAYSIDE TEXTILES LTD. 1931

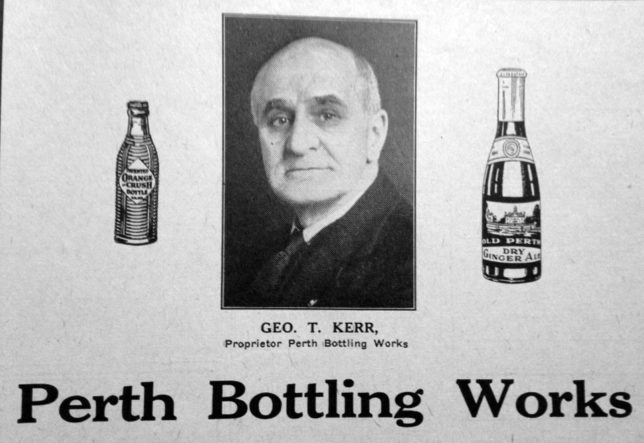

PERTH BOTTLING WORKS BROCK STREET

In 1928 George T Kerr began, in a very modest way, manufacturing and bottling “Old Perth” Beverages. From the beginning business was good and they added other lines of refreshing drinks over the years. As the trend of public habits changed and the sonsumption of “pop” became popular, so did the acceptance for their brands grow. more efficient methods were required to meet the incresased demands, and their new plant was built and equipped with modern, sanitary machines for manufactur and bottling.

In 1928 George T Kerr began, in a very modest way, manufacturing and bottling “Old Perth” Beverages. From the beginning business was good and they added other lines of refreshing drinks over the years. As the trend of public habits changed and the sonsumption of “pop” became popular, so did the acceptance for their brands grow. more efficient methods were required to meet the incresased demands, and their new plant was built and equipped with modern, sanitary machines for manufactur and bottling.

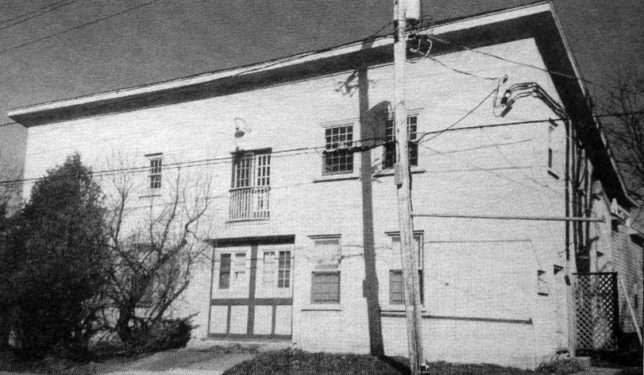

BOLT FACTORY – BOTTLING WORKS – LEWIS STREET

In 1878 Robert Lillie manufactured nuts and bolts in the foundry on the corner of Gore and North Street but moved to this building in 1884 at the end of Lewis Street on the Tay. In 1895, Chrystal Springs Brewery opened here and then closed in 1902. Between 1902 and 1944 the building was home to General Electric Co., Superior Polish Manufactures, Denning Canadian Fence. In 1944, the Perth Bottling Works occupy the building.

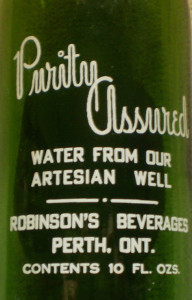

In 1878 Robert Lillie manufactured nuts and bolts in the foundry on the corner of Gore and North Street but moved to this building in 1884 at the end of Lewis Street on the Tay. In 1895, Chrystal Springs Brewery opened here and then closed in 1902. Between 1902 and 1944 the building was home to General Electric Co., Superior Polish Manufactures, Denning Canadian Fence. In 1944, the Perth Bottling Works occupy the building.  Mr. Les Smallwood was the proprietor, the business was previously located on Cockburn street where it was founded by George Kerr. They produced soda water, cream soda, ginger beer, ginger ale, orange crush and siphon soda. In 1953, it became the home of Robinson’s Ginger Ale. The building is now private condominiums.

Mr. Les Smallwood was the proprietor, the business was previously located on Cockburn street where it was founded by George Kerr. They produced soda water, cream soda, ginger beer, ginger ale, orange crush and siphon soda. In 1953, it became the home of Robinson’s Ginger Ale. The building is now private condominiums.

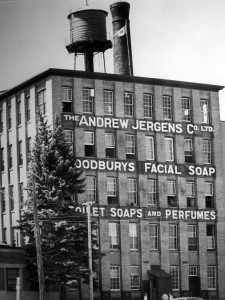

ANDREW JERGENS

In 1912, a two-story building was built for the Andrew Jergens Company in Perth. In 1939, an extra 3 floors were added for the expanded production of soap, skin preparations and cosmetics. In 1988 KOA Corporation of America and Japan bought the plant, but later in 1993 sold to the Perth Soap Company who manufactured private label products.

THE CANADIAN BARK WORKS 1868

The Canadian Bark Works, was started in `1868 to extract tannin (or tannic acid) from the bark of the hmlock tree, which was then so plentiful. It was used in tanning leather. Hundreds of barrels of the extract were shipped annually to Boston, Montreal, etc. and used locally. It closed down in 1874 owing to the diminishing supply of bark. Messrs. John S. Hart, Thomas Aspden, John Hargreaves, Alexander Morris, William J. Morris and Captain John Manion were finacially interested. The plant was located at the south end of the lake..

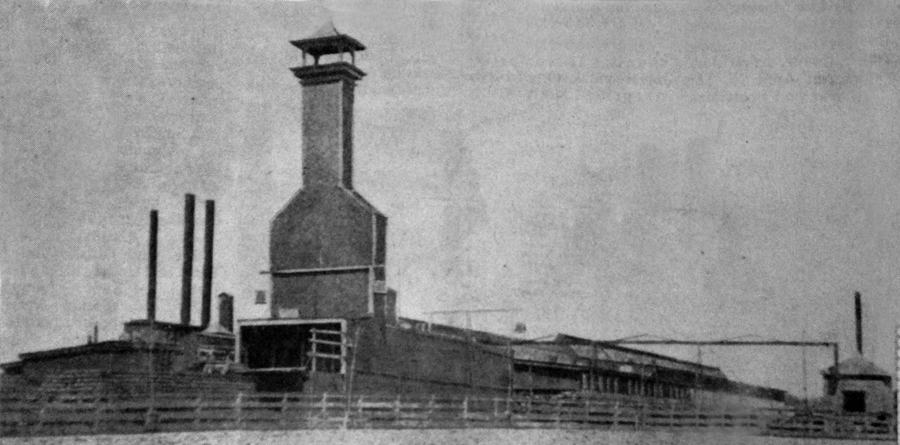

CPR CAR SHOPS 1896

CPR car shops was situated at teh foot of Herriott Street and during its heyday employed over 300 Perth and area residents. The building, which was prone to fire, burned in 1904. Railway cars and other wooden rolling stock were manufactured at this plant.

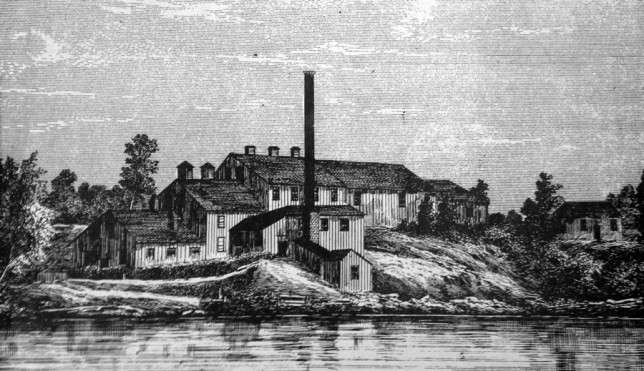

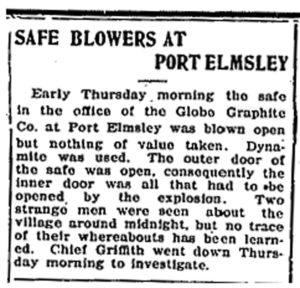

GRAPHITE MINE PORT ELMSLEY

The mine was situated on the Rideau Ferry Road about three miles from the village. A mill was built at the mines, run by steam, but ore could not be successfully processed. In 1901-02 the Globe Refining Co. (an American company) took over the mine. They bought the woolen mill and installed close to $100,000 worth of machinery. Rinaldo McConnell was the manager of the mill. A dam was built above the mill, and remnants still remain. The refinery is operated by the water power from the Tay River and it is intresting to note the process through which the crude ore must go before the grraphite is extracted. The ore is brought in large pieces from the mine, and at Port Elmsley the dry process is used in the refining of this ore. This consists at first of heating or roasting the ore in what is called the roast kiln. It is then put through heavy, coarse crushers, which break the ore up into pieces that will average about an inch square. The ore is further refined by going through three sets of heavy mining rolls, with the operation of which it is reduced to about 1/8th of an inch. Reaching this refinement in size it is further reduced by fine grinding rolls and is then ready to be dusted by the air system, the dust being removed from the ground ore and graphitem after which all the large graphite is removed by what is called a scalper. The finer sands and graphite are then removed by jig tables, which are sufficient to eliminate the balance of the graphite contained in the ore. The graphite then goes through a final process, being taken up with graders and dusters, finally having been completely refined when it goes through the polishing rolls and is ready for the market to be sold by the pound. Much of the earth was stripped from village lots to build the dam. Thirty-five to fifty men and sometimes more were employed. Teams of horses hauled the ore to the mill. Large stables were built and the company’s horses pastured on what is known as the Company Lot. The “Back Dam” is the remains of a dam built by the Graphite Co. The company bought much of the land in the village around 1908 and housing accommodations were provided for the employees. By 1924 the supply of graphite was petering out and it still could not be processed satisfactorily and was abandoned. Eventually beginning in 1930 and ending in 1936, all the graphite property and machinery were sold for taxes by the township.

THE USES OF GRAPHITE after it has been refined are many and various, but it is by far most commonly and widely known as a component of that misnomer – the ever familiar “lead” pencil. Yet, out of the world’s total consumption in the year 1903, when certain graphite stats were compiled, it was estimated that out of 75,000 tons of graphite, no more than four per cent was consumed in the manufacture of lead pencils, Refractory articles such as crucibles, stoppers, nozzles etc accounted for 35% of the consumption, stove polish for 30% and lubricating graphite and greases 16%. Foundry facings, graphite packing and graphite paint, consumed 14% of the product and the last named item alone, when efficiently exploited may be regarded as capable of taking the leading placee in the world’s demand for graphite products.